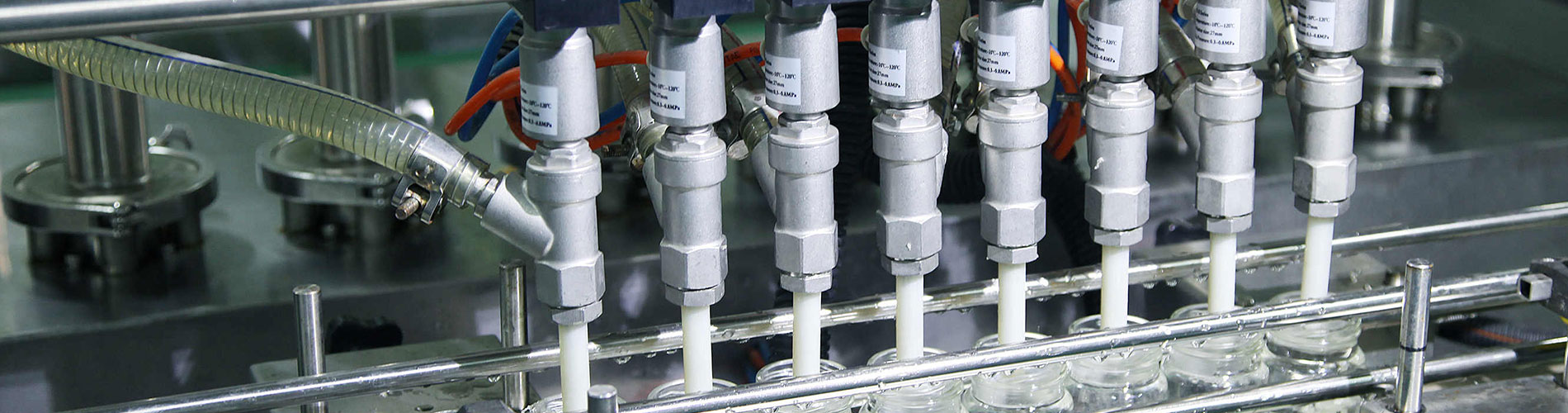

Steel casting

Ut ad fabricam professionalem ferrum dejectionis, ars nostra specialitas late applicatur ad graviores, fortiores, et multiplices formas acquirendasferro mittentes. Cum nobiscum commercia, plura beneficia accipis ut minora gratuita, vilius corona processum pro complexu consiliorum, et accuratius altius. Aliud competitive beneficium, quod a Maple Machinery usurpatum est, in Sinis praecipuum locum habet ad technologiam mittendam. Discutiendi et micron-gradus operas processus accurate providebimus.

- View as

Redivivus Industry Ferro Subsecutio mittit Partes

Machinaria acerna semper supremam qualitatem praebuit Redivivus Industry Ferro Subsecutio Partes Iactandi ministerium. Nostras clientes cum summis qualitatis partibus et officiis praebemus. Our Industry Recycling Steel Precision Parts Service is designed to meet exact needs of our customers and our team is credit to provide valorem per praecisionem engineering and innovative tooling capacities.

Lege plusMitte InquisitionemRedivivus Industry Ferro mittentes Partes

Machina acerna est ferramentum emissum ferro. "Cera perdita" methodus adhibetur ad varias projectiones cum summa subtilitate producendas. Ob hanc generalem accessionem, fabrum nostri magnam latitudinem habent in producto consilio, Industry Redivivus Ferro Partes fundens et materialis lectio. Id est quod, cum vobis consulentes, optimas intentiones redivivae Industriis producere possumus, quae vestris exactis desideriis ac postulationibus occurrent. Machinaria acerna est particeps progressionis tuae ad effectum deducendi, cum meta ad optimam jacturam per mutuam consultationem assequendam.

Lege plusMitte InquisitionemOff via Industry Diver mittentes Partes

Ut optimos parametros Jactantes productum petitum praebeat, machinae acernae fabricare Off Highway Industry Stainless Steel Partes Jacentes utentes novissimam CAD technologiam ut clientes nostros cum cerae injectione formas ad sumptus competitive praebeant. Fixtura quae praebet et sustentat consistentiam dimensivam formae iniectionis cerae per se designatum est secundum dimensiones tractus technicarum partium ad accurate mensuras iterare.

Lege plusMitte InquisitionemOleum & Gas Industry Steel Iactis Partibus

Machinaria acerna processuum omnium generum metallorum et nostra experientia nobis dat ut facilius conficiatur oleum & Gas Industry Stainless Chalybe Conjecting Parts Stainless chalybe, una ex communi materia in laboratorio nostro. Nos efficit ut perfecta officia per societates provideamus et solutiones technicas et oeconomicas provideamus adaptivis, diversis fontibus copiae. Interne integram integram productionis catenam invigilet, alacritate, technica magisterio et qualitate. Et suggestiones ad ipsum oeconomicum.

Lege plusMitte InquisitionemMachinarium agriculturae Steel iactans Partes

We have rich experience in the field of steel, steel, aluminum, special alloy and other agricultural machinery. All Agricultural Machinery Stainless Steel Casting Parts are made by different processes, including sand casting, investment casting, centrifugal casting, die casting, forging, machining, etc. We have been serving international industrial markets for more than 15 years. Our primary goal is to retain the loyalty of existing customers and win new business through exemplary customer service, low cost, high quality, fast shipping, complete order fulfillment and custom processing. 产品内容 Agricultural Machinery Stainless Steel Casting Parts Product Introduction Maple machinery's services include heat treatment, machining and surface treatment. Heat treatment involves heating and cooling a metal to change the physical and mechanical properties of Agricultural Machinery Stainless Steel Casting Parts. Heat treatment controls properties such as hardness, strength, toughness, ductility, and elasticity. We also offer a full range of machining services. With our surface treatment service, we can treat your products to improve corrosion resistance, wear resistance and appearance. 2. Product Parameter (Specification) Item Agricultural Machinery Stainless Steel Casting Parts Roughness Ra 1.6 Tolerance ±0.01mm Material Casting Steel Certification ISO 9001:2015 Weight 0.01-2000KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Investment Casting Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Service for Agricultural Machinery Maple machinery is one of the trusted and reliable manufacturers and suppliers of Stainless Steel Casting Parts, Vick serves the global needs of Agricultural Machinery Stainless Steel Casting Parts and ensures high quality products and on-time delivery in every transaction. In our foundry, we mainly process carbon steel and alloy steel materials. We inherited the casting process from our great-grandfather, and have a skilled labor force and professional technical experts to meet different needs. 4.Supporting Service for Agricultural Machinery As mentioned above, in order to work in adverse conditions, the performance of the Agricultural Machinery Stainless Steel Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Mining Industry We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Agricultural Machinery Stainless Steel Casting Parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for The Agricultural Machinery We have manufactured a wide range of Agricultural Machinery Stainless Steel Casting Parts. The following are typical products: Brackets, Rototiller tines, Tillage Points, Seed Drills, Chain Sprocket Locust Harrows, Levers, Plough, Pivots, Covers, Clevises, Handles and Latches, Suitcase Weights, Pumps & Valves, and Hardware.. 6.Why Investment Casting Investment casting is a leading process used for the production of high-quality castings and is used to make metal alloys. The key advantage of the investment casting process is that it can help to cast metals with high melting temperatures and create parts with complex geometry that are much needed in industries like aircraft, automotive, and military. As professional investment casting manufacturer, our specialized technique is widely applied to get heavier, stronger, and complex shapes for investment castings. When you trade with us, you get several benefits such as lower costs, a cheaper molding process for complex designs, and higher accuracy. Another competitive benefit enjoyed by Maple Machinery is its leading position in China for casting technology. We will provide precision castings and micron-level processing services.

Lege plusMitte InquisitionemHydraulic System Steel Lost Cera Iactis Partibus

Machinaria acerna in modernis et urbanis instrumentis collocat ad omnia requisita emptoris ad systema Hydraulicum Ferro Amissum Ceram Partes mittentes secundum fidem, iterabilem et flexibilitatem. Machinaria acerna multam experientiam habet in cera amissa mittendo et certificationes industriales quae omni tempore renovantur et emendantur.

Lege plusMitte Inquisitionem