Marine Stainless Steel Iactis Partibus

Mitte Inquisitionem

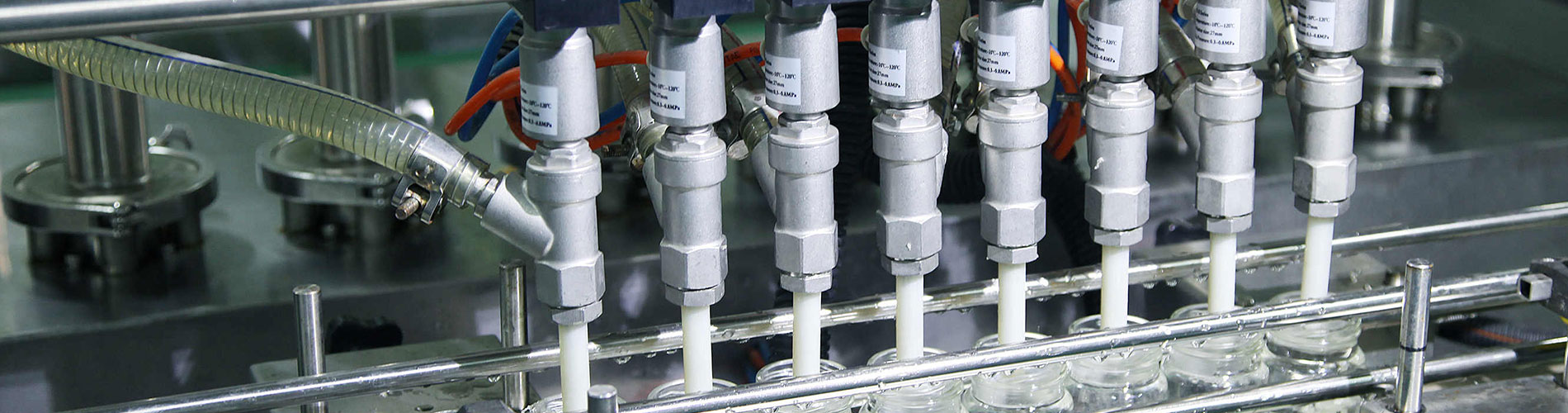

Acer machina amplis consuetudinis offert Marine Stainless Steel Partes Iactans. Chalybs immaculata repugnant corrosioni et calori, aestheticam appellationem habet et sumptus vitae cycli humilis, plene redivivus est et bonam vim habet ad pondus-proportio. Offerimus gradus austenite, ferrite, martensite et biphasi: nos calidum vel frigidum involutum et varias curationes superficiei, sicut furnum lucidum. Experientiam nostram dinumerare potes.

Parameter Product (specification)

|

Item |

Marine Stainless Steel Iactis Partibus |

asperitas |

Ra 1.6 |

|

tolerantia |

±0.01mm |

Materia |

Dejectio Steel |

|

Certification |

ISO 9001:2015 |

Pondus |

0.01-2000KG |

|

Machining |

CNC |

Calor treatment |

Exstingui & Tempering |

|

inspicienda |

MT/UT/X-Ray |

Duc Tempus |

XXX diebus |

|

sarcina |

Plywood Case |

Methodus |

Investment Iactare |

|

capacitas |

(L) Pcs / Mensis |

Origin |

Ningbo, China |

Mapleâs Service pro Marine

Machinaria acerna exactissima machinalis Marine Stainless Steel Partes iaciens plus quam 15 annos fuit. Fama nostra meruit socios et clientes aestimatos qui severissimas exigentias sequuntur secundum microstructuram integritatem, tolerantias dimensivas et qualitatem temperantiae. Our products meet customers' requirements and standards.

Supporting Service for Marine

◉ Ut supra dictum est, ut in adversis condicionibus laborandum sit, praestantia praestatio Partes Marine Stainless Steel Iactantis esse debet. Ideo non satis est ad crudas modos iactationes vel cucursiones producendas, sed etiam opus caloris curationis, machinationis, curationis superficiei, NDT probatio, etc.

◉ Curatio caloris: curatio caloris gradus est ad emendandum proprietates mechanicas workpiece. Processum secundum vires exigentias partium formare possumus, et proprietates mechanicas partium emendare ut duritiem, cedere vires, vires distrahentes et elongationem per curationem caloris.

◉ Machinatio: machinam nostram habemus tabernam, et omnia fere necessaria machinis cum apparatu provectorum complere possumus.

◉ Curatio superficiei: Propositum curationis superficiei est partes operari in adversis environment. Cadmiae partes rubiginem prohibere possunt; Nickel plating potest augere resistentiae et corrosionis partium resistentia; Phosphating partes impedire potest ex corrosionâ¦

◉ Non perniciosa probatio (NDT): NDT est ultimus ac maximus gradus. Acer partes NDT curabit ut nullae sint defectiones superficies (ut rimas, foramina arenae, perforata sufflaia) nec defectus interni (schrectio et scoria) in partibus traditis.

Commune Materiam Mining Industry

Facultatem habemus ad fabricandum omnes materias ferri vexillum necnon materias speciales. Hae sunt communes materiae ad fabricandas partes Marine Stainless Steel Iaculantes:

Carbon Steelï¼1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45â¦

Admisce Steelï¼4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMoâ¦

Immaculata steelï¼304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20â¦

Ironï¼GG-15, GG-20, GG-25, Classis XXB, Classis XXVB, Classis 30B, GJL-CCL, GJL-300â¦

Ductile Ironï¼GGG-40, GGG-L, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2â¦

Princeps Chromium misit ironï¼15% Cr-Mo-HC, 20% Cr-Mo-LC, 25% Crâ¦

Aluminiumï¼AlSi7Mg, AlSi12, AlSi10Mg, A356, A360â¦

Princeps Manganese chalybe: X120Mn12, Mn12, Mn13â¦

Partes supplentes pro Marine

Marinus Stainless Ferro Partes mittentes amplis fabricavimus. Producta typica sunt: Instrumenta in terra ineunt: terebra frena, instrumentum praefixum carbide, situla dens ficti, auger....

Quare Tractatus Iactis

Conjectio investiendi est processus praecipuus ad proiectionem quali- tatis producendis et admixtionem metallicam facere adhibetur. Praecipua utilitas processus mittentis obsidendi est quod adiuvare potest ad metalla alta cum temperaturis liquefactis et partes creare cum complexu geometriae, quae multum necessariae sunt in industriis sicut aircraft, automotive, et militaris.

Ut professionalis obsidionis deiectionis opificem, nostra ars specialitas late applicatur ad graviores, validiores, et multiplices formas ad dejectiones collocandas. Cum nobiscum commercia, plura beneficia accipis ut minora gratuita, vilius corona processum pro complexu consiliorum, ac accuratius altius. Aliud competitive beneficium, quod a Maple Machinery usurpatum est, in Sinis praecipuum locum habet ad technologiam mittendam. Discutitiones et micron-gradus processus operas accurate providebimus.