Off via Industry Steel Lost Cera Iactis Partibus

Mitte Inquisitionem

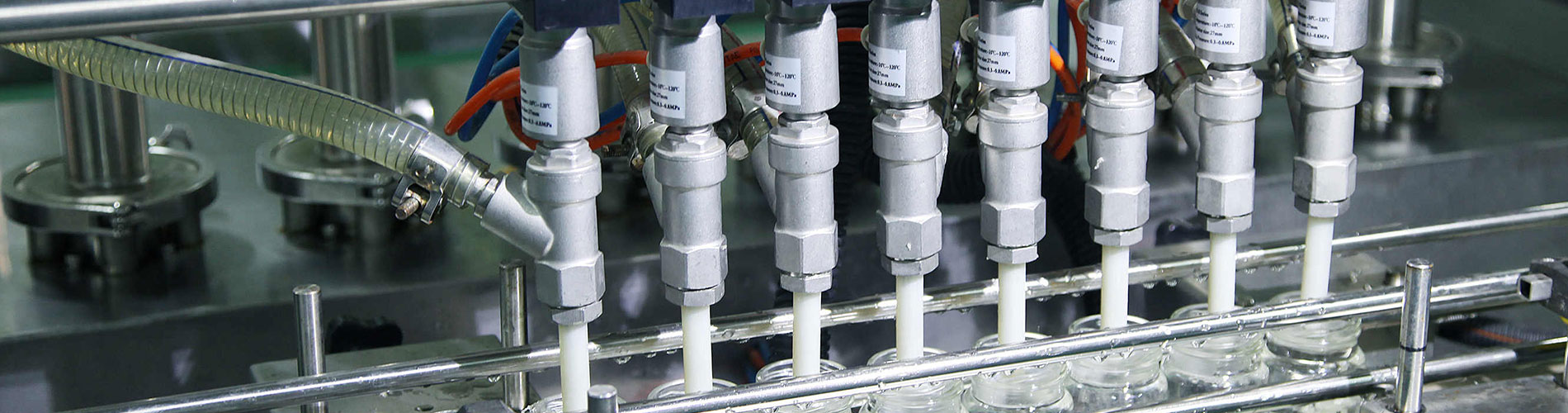

Off Highway Industry Steel Lost Cera Projiciens Partsis productum quod Maple machinamentum fecit. Cera dejectio perdita, quod nunc mittentes obsideri dicuntur. Praecisio est processus fundendi cum incisione parum vel sine. Non solum ad subtilitatem varia genera et mixturas dejectiones apta est, sed etiam in altioribus subtilitatis et superficiei qualitates obiectiones producit quam alia subtilitate methodorum emittentes. Ad usus diversorum clientium, duplici genere cerae utimur, scilicet ceram flavam low temperatura et ceram viridem mediae temperaturae.

Parameter Product (specification)

|

Item |

Off via Industry Steel Lost Cera Iactis Partibus |

asperitas |

Ra 1.6 |

|

tolerantia |

±0.01mm |

Materia |

Ferro mittentes / Iron |

|

Certification |

ISO 9001:2015 |

Pondus |

0.01-5000KG |

|

Machining |

CNC |

Calor treatment |

Exstingui & Tempering |

|

inspicienda |

MT/UT/X-Ray |

Duc Tempus |

XXX diebus |

|

sarcina |

Plywood Case |

Methodus |

Arena Casting |

|

capacitas |

(L) Pcs / Mensis |

Origin |

Ningbo, China |

Mapleâs Services pro Off via Industry

Machinaria acerna fabricandi facultatem augebat ad Highway Industry Steel Amissa Cera Partes iactandi per multos annos. Provide excelsum qualitas Off Highway Industry Steel Lost Ceram Partes Iactandi pro nostris operationibus machinandis ad occursum et satisfaciendum necessitates emptoris. Discurrere possumus varia genera iactationum, inter quas: pressus mori iactus et iactus harenae. Clientibus nostris adiuvamus ut aptissimum genus emissionis secundum inquisitionem voluminis et multiplicitatem desumamus, solutionem efficacissimam praestantissimam praebentes.

Sector ferriviarius praebet retiaculum crucialem ad transportandum et distribuendum. Sumptu-efficax et diuturna instrumenta indiget quae pro applicationum amplitudine constanti est. Balneae, a vectura vecturae, diversis applicationibus ad varia medicamenta indigent. Machina acerna magnam experientiam fert ad creandum fusuras ferreas et fusuras ferreas in variis magnitudinibus, figuris, materiis, quae praecise, validae et durabiles sunt. Amplis iactationibus et malleolis fabricamus ad apparatum ferriviarium infrastructuram et translationem.

Supportantes Service pro Off via Industry partes

◉ Ut supra dictum est, ad operandum in adversis condicionibus, exsecutio in via Off Highway Industry Ferro Amissa Cera Partes Iactandi optima esse debet. Ideo non satis est ad crudas modos iactationes vel cucursiones producendas, sed etiam opus caloris curationem, machinationem, curationem superficiei, NDT probatio, etc.

◉ Curatio caloris: curatio caloris gradus est ad emendandum proprietates mechanicas workpiece. Processum secundum vires exigentias partium formare possumus, et proprietates mechanicas partium emendare ut duritiem, cedere vires, vires distrahentes et elongationem per curationem caloris.

◉ Machinatio: machinam nostram habemus tabernam, et omnia fere necessaria machinis cum apparatu provectorum complere possumus.

◉ Curatio superficiei: Propositum curationis superficiei est partes operari in adversis environment. Cadmiae partes rubiginem prohibere possunt; Nickel plating potest augere resistentiae et corrosionis partium resistentia; Phosphating partes impedire potest ex corrosionâ¦

◉ Non perniciosa probatio (NDT): NDT est ultimus ac maximus gradus. Acer partes NDT curabit ut nullae sint defectiones superficies (ut rimas, foramina arenae, perforata sufflaia) nec defectus interni (schrectio et scoria) in partibus traditis.

Commune Material pro Off Highway Industry partes

Facultatem habemus ad fabricandum omnes materias ferri vexillum necnon materias speciales. Hae sunt materias communes ad fabricandas Vias Industry Ferro Amisso Cera Iaculando Partes:

Carbon Steelï¼1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45â¦

Admisce Steelï¼4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMoâ¦

Immaculata steelï¼304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20â¦

Ironï¼GG-15, GG-20, GG-25, Classis XXB, Classis XXVB, Classis 30B, GJL-CCL, GJL-300â¦

Ductile Ironï¼GGG-40, GGG-L, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2â¦

Princeps Chromium misit ironï¼15% Cr-Mo-HC, 20% Cr-Mo-LC, 25% Crâ¦

Aluminiumï¼AlSi7Mg, AlSi12, AlSi10Mg, A356, A360â¦

Princeps Manganese chalybe: X120Mn12, Mn12, Mn13â¦

Partes supplemus pro Off via Industry

Facivimus amplis Off Highway Industry Steel Amissus Ceram Iaculans Partes. Producta typica sunt: Copulatio, laminae Centre, uncis ferens, rotae Rail, Rota centrum, lamina base, Axem pixides, Iugalia, Pedes, cardines, lamellas ligamen, Maxillarum tondeum, et iuncturam vectem.

Cur Sand Casting?

Arena dejectio est processus antiquus in quo partes metallicae funduntur ex fundendo metallo in cavum cavum. Processus fabricationis forma substructio adhibetur ad fusuras cum materia ferrea, chalybe, et aluminium facere. Constructio substructio plures gradus comprehendit et amplis figuris et magnitudinum productorum metallorum creare potest. Processus incipit a confectione formarum formarum et systematis portae cum mensura et figura partis inquisitae. Temperatura requiritur a metallo dependet, sicut aliqua metalla diu calefacere et liquescere.

Machina acerna continenter apparatum Sand-iciendi suum upgraded et processum iectionis expolivit. Propositum post hoc est solum progressus technologias pro operationibus Sand-iciendis. Unusquisque gradus sequitur picturas et instructiones ad solutiones certas tradendas.