Nos voca

+86-19858305627

Inscriptio Us

sales@maple-machinery.com

Ferrum Marine Partes pro Diesel Engines Manufacturers

Officina nostra praebet arenam iacturam, clausa mori cudendo, aperta mori cudendo, etc. Extremum consilium, materias rudis qualitas, princeps effectus ac pretium competitive sunt quae omnis mos velit, et id etiam quod tibi offerre possumus. Summus quale, rationabile pretium, et perfectum servitium.

Hot Products

Oleum & Gas Industry Ferro Propinquus Die Partibus Forging

Machina acerna est societas quae solutiones cudendi viginti annis praeteritorum dedit. ISO9001 praeterivimus certificationem. Nulla defectus ad signa fabricanda nostra pertinet, et omnes processus in domo cum infrastructura primae classis conservari curamus. Superbi sumus de experientia nostra et communicatio aperta cum victualibus ad explicandum oleum & Gas Industry Ferro Clausis Die Forging Partibus, signa occursum mos designandi et partus qualitas products celeriter praebent.Mining Industry Steel Lost Cera Mittentes Partes

Nostra Mining Industry Ferro Amissa Cera Iactandi Partes late in fodiendis et mineralibus campis processui adhibentur. Qualitate alta et stabili, plusquam XX annos experientiae professionalis habemus. Protulimus technologiam technologiam, quae explosione-probationis technicae requisitis machinis fodiendi clientium occurrere potest. Si solutiones ab aspectus consilii, simulationis, abiectionis et machini tibi praebere debes, et aliqua efficacia suggestiones praebere ad exsequendam Mining Industry Ferro Lost Ceram mittentis Partes, laeti sumus ut peritiam tuam efficiamus.Oleum & Gas Industry Gray Partes Iactans

Ex Gray Irono fabrum mittentes, technici, exactores fabricandi mechanici et exemplar aedificantes in productione ad mechanicos et electronicos technicos industriales seu adiutores industriae in sustentatione, opera sua cotidie placent nostris Oleo & Gas Industry clientibus magna qualitate abiectionis. Ex consulto et ordine processus, ad praeparationem et productionem Olei & Gas Industry grisei ferrei partes mittentes, ad profunde processus et vecturas, sicut equos, propositum communem persequimur: ad producendum partes mittentes complexas et altas qualitates ferreas griseas.Cibus Processus Machina Steel Iactis Partibus

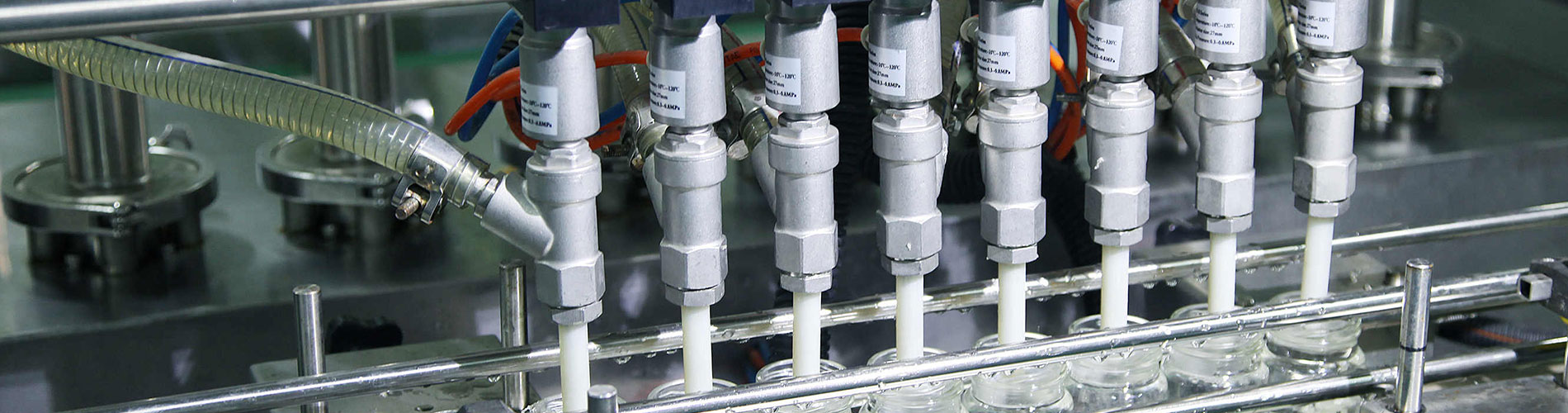

Acer machinarum machinationum certificata ratio qualitatis administrationis efficit ut norma et ratio progressionis optimized sint in negotiis nostris hodiernis negotiis. Quam ob rem internis processibus ac fructibus continuas emendare possumus. Fac ut omnis Cibus Processus Machina Ferro Partes Iactandi sint ad vexillum. Machina acerna serviens clientibus in Processu Machinae Cibus industriae fuit. Bonae res etiam factae sunt.Iactus Iron Partes ductiles

Machinaria acerna, cum technica sua ampla scientia et quadrigis maxime idoneis, nativus Ductilis Partes ferreas in solutiones alignment cum necessitatibus clientium nostrorum evolvit. Secreto, accountability, et sustineri praevia secreto in relationibus cum omnibus quorum interest, cum medio Valvae - et diu terminus metas in mente. Requisita technica mutuae conventionis cum emptoris officia definita praebent. Turma ministerium velox responsionem quaerit et diaphaneitatem directam ab evolutione projecti ad post-venditionem quaerit. Praebere solutiones ejicere secundum exigentias mos et specificationes.Redivivus Industry Ferro mittentes Partes

Machina acerna est ferramentum emissum ferro. "Cera perdita" methodus adhibetur ad varias projectiones cum summa subtilitate producendas. Ob hanc generalem accessionem, fabrum nostri magnam latitudinem habent in producto consilio, Industry Redivivus Ferro Partes fundens et materialis lectio. Id est quod, cum vobis consulentes, optimas intentiones redivivae Industriis producere possumus, quae vestris exactis desideriis ac postulationibus occurrent. Machinaria acerna est particeps progressionis tuae ad effectum deducendi, cum meta ad optimam jacturam per mutuam consultationem assequendam.

Mitte Inquisitionem

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy