Nos voca

+86-19858305627

Inscriptio Us

sales@maple-machinery.com

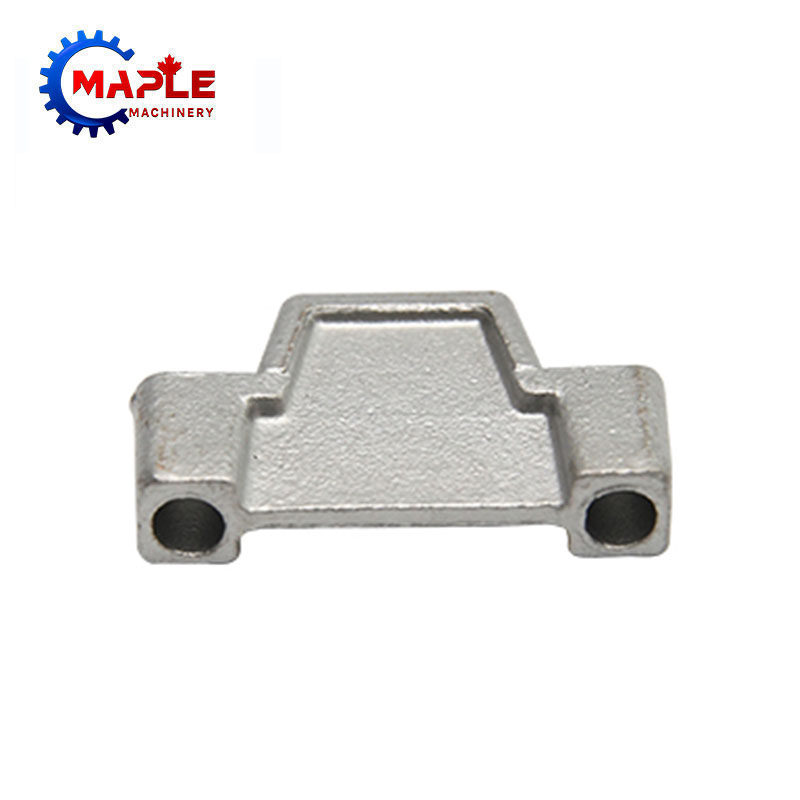

Iactus Iron Partibus ductilis Manufacturers

Officina nostra praebet arenam iacturam, clausa mori cudendo, aperta mori cudendo, etc. Extremum consilium, materias rudis qualitas, princeps effectus ac pretium competitive sunt quae omnis mos velit, et id etiam quod tibi offerre possumus. Summus quale, rationabile pretium, et perfectum servitium.

Hot Products

Off via Industry Ferro elit iactantes Partes

Acer Machinaria utitur technologia professionali et peritia ad designandum et producendum summus qualitas products. Coniecturae subtilitate a nobis factae utimur in toto orbe terrarum cursu plenas blasphemantes. Collaboramus et laboramus cum pluribus magnarum machinarum ferriviarum partibus in mundo. Our customers use our Off Highway Industry Steel Investment Parts Iactantes cum fiducia propter nostram comprehensivam qualitatem moderandi signa. Spondemus hasteel fusuras et malleolos a nobis factas pro Industriis Highway certas esse.Gravis Industry Steel Lost Cera Iactis Partibus

Per robustam qualitatem administrationis systematis, acerbum adhaesio ad signa stabilita, inexorabilis focus in praecisione, et assidua emendatio et satisfactio emptoris - haec omnia elementa sunt quae adiuvant nos liberam qualitatem gravem Industry Steel Lost Ceram Partibus nostris clientibus mittentes. regat.Redivivus Industry Ferro Propinquus Die Partibus Forging

Quaecumque figuram tuam Redivivus Industriis Ferro Clausus Die Forging Partes sunt, si partes metalli requiruntur, Data Industrialis Venditio pro te in Machinaria Maple nativus esse potest. Hae paucae industriarum sunt propter quas proprias falsas et iactationes creamus: aerospace Automotivi constructionem & apparatum gravem fabricandi & metallatoria forestry Mining Oil & Gas.Oleum & Gas Industry Steel Sand Iactis Partibus

Machinaria acerna fabricat qualitatem Olei & Gas Industry Ferro Sand Partes fundentes Olei & Gas Industriis per orbem terrarum. Propositum est optio mercaturae et solutiones certiores pro Olei & Gas Industry Chalybe Sand Partes emittentes praebere, et curare ut partes qualitates optimas creando, non solum diutius maneant et tempore suppeditentur, sed etiam ad sumptus inferiores; Sic oeconomia temporis obscuratis emptoris ut partes qualitatis summae.Machinery Ductile Construction Ferri Iactis Partibus

Societas plus quam decem annos experientiae habet in Constructione Machinery Ductile Ferri Partes Iactandi. Utendo computatoribus et lineis productionis automated, optimam consequi possumus methodum mittendi, formas multiplices creandi, lineas torcular fabricandi, lineas emissas removendo, et iactantia tolerantias dimensionales altissimas producens.Marine Steel Precision Parts

Acer Machineria habet professionalem armorum dejectionem et experientiam copiosam in Marine Steel Praecisione Partibus Iactis. Locus egregius et prope portum. Singulariter nostra est modus faciendi ferrum pro navibus. Auxilium clientium nisi sumptus et breviare tempus productionis. Melior qualitas productionis.

Mitte Inquisitionem

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy