Nos voca

+86-19858305627

Inscriptio Us

sales@maple-machinery.com

Ferri machina ductilis Manufacturers

Officina nostra praebet arenam iacturam, clausa mori cudendo, aperta mori cudendo, etc. Extremum consilium, materias rudis qualitas, princeps effectus ac pretium competitive sunt quae omnis mos velit, et id etiam quod tibi offerre possumus. Summus quale, rationabile pretium, et perfectum servitium.

Hot Products

Construction Machinery Steel Lost Cera Iactis Partibus

Tota Constructio Machinery Ferro Amissa Cera Proiciens Partes Mappae machinae cum internis viribus et integritate fabricantur. Per processum sophisticatum perditum Ceram mittentem, partes producere possumus severis tolerantibus. Acer machinae solidificatione utitur programmate exemplarium ad praedictionem qualitatis internae graduum dejectiones antequam partes fabricantur, multum minuens tempus ad mercatum et progressionem gratuita per "iudicium et errorem" accessus ad progressionem processus.Agricultural Machinery Ductile Iron Partibus Iactis

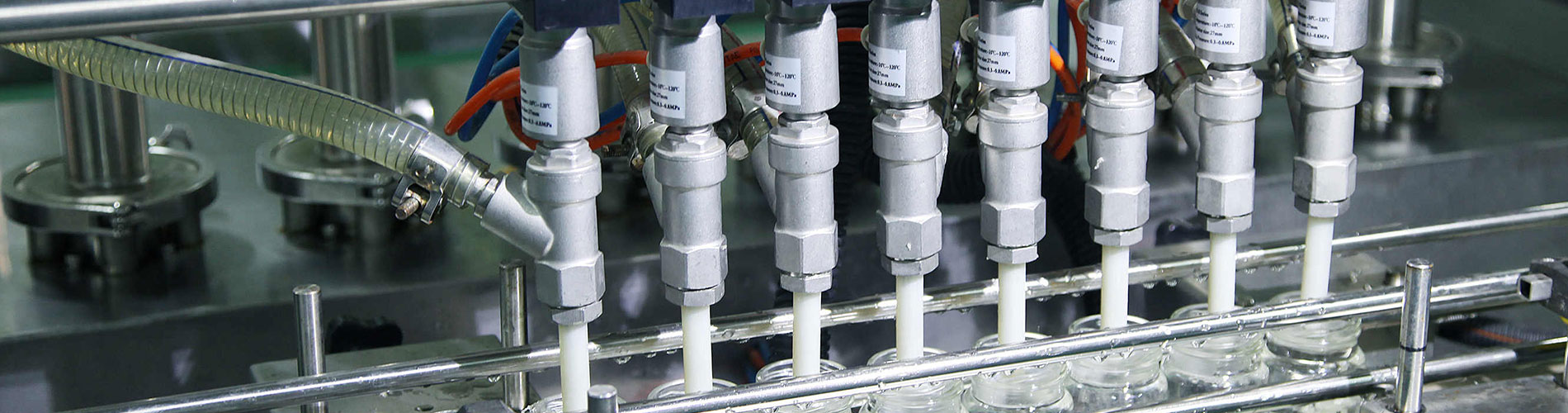

Supplementum productorum ferri ductilis ad plus quam XV annos machinis acernis est opifex professionalis machinae agriculturae machinae ductiles partes ferreae mittentes, item ad fodienda, praedandi, generandi et machinandi industrias potentia generandi amplis valde obsistentibus admixtionibus et ferro et ferrei flatura ferrei. ISO 9001 qualitas certificata opificem, cum summa qualitate fundorum ad artifices mundi agriculturae et mundi instrumenti agriculturae praefectis provideat.Cibus Processus Machina Diver Partibus Forging

Duobus fere decenniis, officina nostra in Ningbo, Sinarum Processus Machinam Steel Forging Partes ad satisfactionem clientium nostrorum producere fecit. Per upgrading facultatis nostrae machinae et productionis super annos, nunc omnia genera signa et Processus Machinae Victus offerre possumus Steel Forging Partes usquam foris.Mining Industry Grey Iron Partibus Iactis

Machina acerna est Mining Industry Gray Iron Partes mittentes opificem ad Industry Mining. Praebentes fructus, speciales productorum metallurgicorum et armorum productiones, ac necessaria subsidia consulendi praebemus. Cum supra XV annos experientiae in his industriis, adiuvare possumus optimam technologiam et apparatum invenire pro processibus curationis superficiei Gray Ferri dejectionem et processuum.Civilis Engineering Ferro Subsecutio Partibus Iactis

Machinaria acerna est fabrica ferro Praecisionis Partes mittentes pro variis necessitatibus industriae. Nos gloriamur nos ad valorem additis ferro praecisionis Partibus Iactis. Engineering Steel Precision Parts Casting is one of our many products, Nos experti sumus in fabricandis Engineering Steel Praecisione Partibus Iactis. Fiducia ex nostris plusquam XV annis experientiae fabricandi venit.Machinarium agriculturae Steel iactans Partes

We have rich experience in the field of steel, steel, aluminum, special alloy and other agricultural machinery. All Agricultural Machinery Stainless Steel Casting Parts are made by different processes, including sand casting, investment casting, centrifugal casting, die casting, forging, machining, etc. We have been serving international industrial markets for more than 15 years. Our primary goal is to retain the loyalty of existing customers and win new business through exemplary customer service, low cost, high quality, fast shipping, complete order fulfillment and custom processing. 产品内容 Agricultural Machinery Stainless Steel Casting Parts Product Introduction Maple machinery's services include heat treatment, machining and surface treatment. Heat treatment involves heating and cooling a metal to change the physical and mechanical properties of Agricultural Machinery Stainless Steel Casting Parts. Heat treatment controls properties such as hardness, strength, toughness, ductility, and elasticity. We also offer a full range of machining services. With our surface treatment service, we can treat your products to improve corrosion resistance, wear resistance and appearance. 2. Product Parameter (Specification) Item Agricultural Machinery Stainless Steel Casting Parts Roughness Ra 1.6 Tolerance ±0.01mm Material Casting Steel Certification ISO 9001:2015 Weight 0.01-2000KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Investment Casting Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Service for Agricultural Machinery Maple machinery is one of the trusted and reliable manufacturers and suppliers of Stainless Steel Casting Parts, Vick serves the global needs of Agricultural Machinery Stainless Steel Casting Parts and ensures high quality products and on-time delivery in every transaction. In our foundry, we mainly process carbon steel and alloy steel materials. We inherited the casting process from our great-grandfather, and have a skilled labor force and professional technical experts to meet different needs. 4.Supporting Service for Agricultural Machinery As mentioned above, in order to work in adverse conditions, the performance of the Agricultural Machinery Stainless Steel Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Mining Industry We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Agricultural Machinery Stainless Steel Casting Parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for The Agricultural Machinery We have manufactured a wide range of Agricultural Machinery Stainless Steel Casting Parts. The following are typical products: Brackets, Rototiller tines, Tillage Points, Seed Drills, Chain Sprocket Locust Harrows, Levers, Plough, Pivots, Covers, Clevises, Handles and Latches, Suitcase Weights, Pumps & Valves, and Hardware.. 6.Why Investment Casting Investment casting is a leading process used for the production of high-quality castings and is used to make metal alloys. The key advantage of the investment casting process is that it can help to cast metals with high melting temperatures and create parts with complex geometry that are much needed in industries like aircraft, automotive, and military. As professional investment casting manufacturer, our specialized technique is widely applied to get heavier, stronger, and complex shapes for investment castings. When you trade with us, you get several benefits such as lower costs, a cheaper molding process for complex designs, and higher accuracy. Another competitive benefit enjoyed by Maple Machinery is its leading position in China for casting technology. We will provide precision castings and micron-level processing services.

Mitte Inquisitionem

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy