Nos voca

+86-19858305627

Inscriptio Us

sales@maple-machinery.com

Gravis officium ferri fusuras olei et gas sector Manufacturers

Officina nostra praebet arenam iacturam, clausa mori cudendo, aperta mori cudendo, etc. Extremum consilium, materias rudis qualitas, princeps effectus ac pretium competitive sunt quae omnis mos velit, et id etiam quod tibi offerre possumus. Summus quale, rationabile pretium, et perfectum servitium.

Hot Products

Mining Industry Steel Sand Casting Parts

Per Sand Casting, partes complexae produci possunt. Hoc commodum est in fabricandis, cum nullus alius conventus requiratur. Periti sumus in administratione processus mittentes, ex inquisitione formae ad Mining Industry Ferro Sand Partes mittentes ad materias et modos designantes. Invento optimam productionem miscere pro clientibus nostris Mining Industry, invenire potissimam viam ad fructus liberandos.Mining Industry Ferro partes Forging

Machina acerna est unus-extremus fabricandi peritus in fundamentis et machinis, cudendi et abiectionis arcte affinis. Ideo machinae acernae professionalem Mining Industry Ferro Forging Partes pro clientibus plus decem annis ab eius institutione comparaverunt. Instrumentum fictorium in officina nostra non habemus, sed tres officinas fictis cum excellentibus technicis Ningbo instituerunt cooperationem nobiscum ultra decem annos. Negotiationem internationalem nullam habent, sed capacitas fictorum locorum praestantior est. Habuerunt fictis instrumentis. Attritio premit machinam 300t, 400t, 600t, 1200t et 1600t potest fodinas producere tam parvas quam justos P. et quam maximum quam 60kg.Diver Engineering Partibus Forging

Momentum chalybeis immaculati generis radiis in lato mundo constructionis, machinalis, constructionis et structuris chalybis. Tigna ferri immaculata fictae fuerunt momenti pars Engineering Civilis per XV annos. Sicut Steel Partes elit, acerna machina varias machinas civiles efficit Diver Diver Partes Forging Forging pro te a nostris quadrigis. Nos sumus confidebat fabrica partium tuarumGravis Industry Ductile Iron Partibus Iactis

Ningbo, Sinis prope portum sita, suam plantam productionem habet, itemque manipulus machinalis dicatus est ut clientibus solutiones operis cum qualitate et ultimis technicis operibus praebeat. Toti servit mundo. Nostra peritia, nostra moderna machina et magna qualitas technologiae productionis technicae scaenae tradit rectam quantitatem altae qualitatis Gravis Industry Ductilis Ferri Iactantis Partes.Hydraulic System Stainless Steel Iactis Partibus

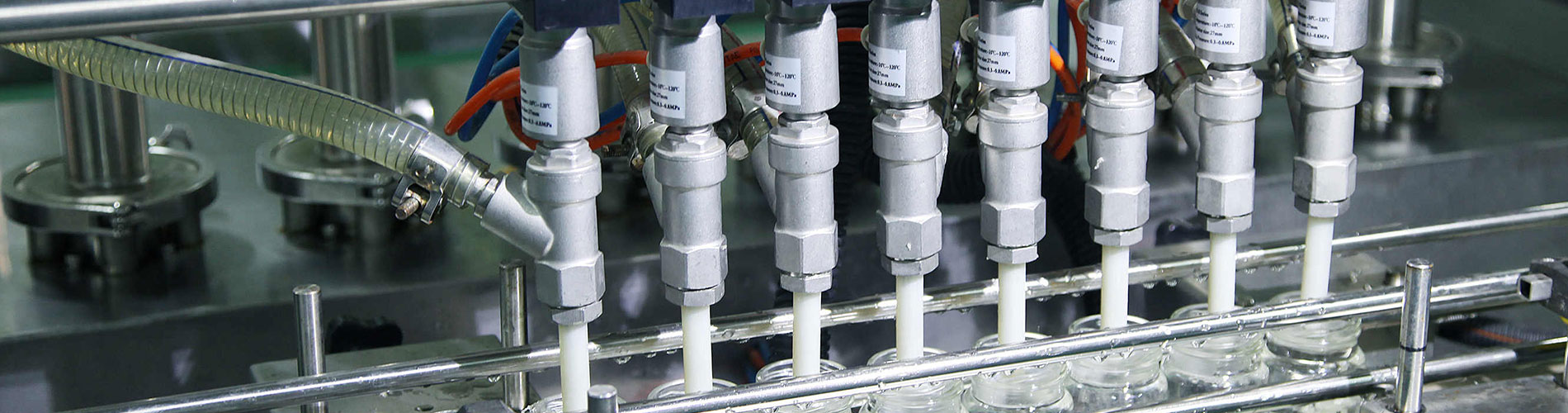

Acer machinae Hydraulicae Systematis Stainless Steel Partes emittentes notum est propter eius fidem, sed opus nostrum ethica innixa fide non cessat. Facere volumus ut in omnibus operis nostri partibus, ex nostris fructibus ad operas et societates Lorem. Superbimus nos in aedificandis longi temporis relationibus Lorem.Cibus Processus Machine Grey Iron Partibus Iactis

Nostra societas cibus Processus Machinae Grey Iron Partibus Iactis magna fama gaudet inter finem usorum qui varias machinae instrumenta et machinas metallorum secantium fabricant. Amplis iactationibus in processu machinis cibis generatim adhibentur. Nos quoque apparatum mortis nucleum praebemus, hoc instrumentum accommodatum ad technologiam metallicam nostram emissionem, quae praestat qualitatem internarum et exteriorum superficierum fusurarum.

Mitte Inquisitionem

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy