Nos voca

+86-19858305627

Inscriptio Us

sales@maple-machinery.com

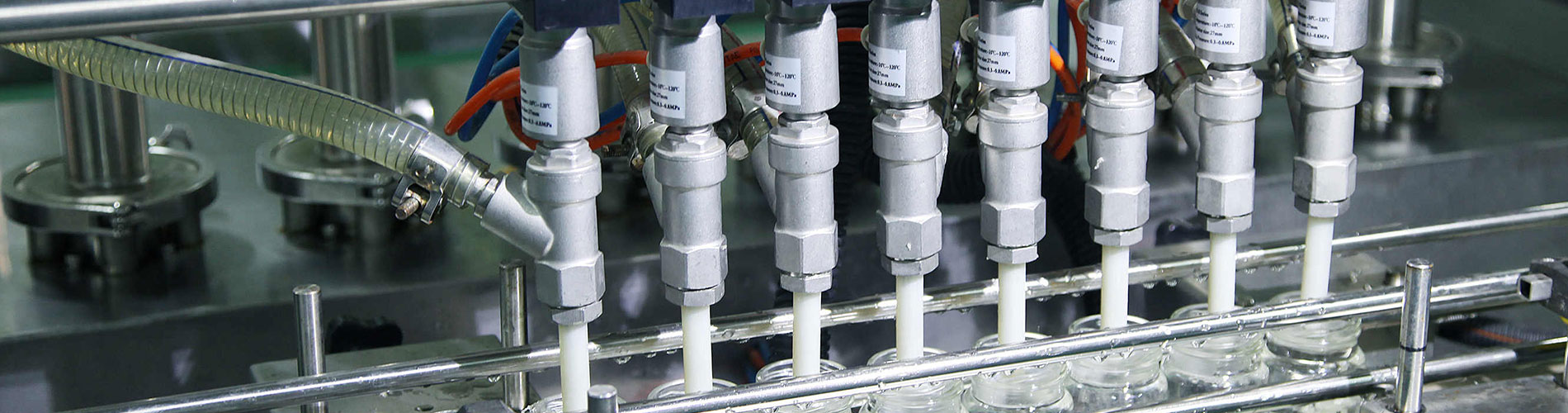

Materia tractatio apparatu investment cast components Manufacturers

Officina nostra praebet arenam iacturam, clausa mori cudendo, aperta mori cudendo, etc. Extremum consilium, materias rudis qualitas, princeps effectus ac pretium competitive sunt quae omnis mos velit, et id etiam quod tibi offerre possumus. Summus quale, rationabile pretium, et perfectum servitium.

Hot Products

Valve Ductile Iron Partibus Iactis

Machinaria acerna, cum suis ampla scientia technica et quadrigis maxime idoneis, evolvit valvae ductile ferrum emittens Partes solutiones in alignment cum necessitatibus clientium nostrorum. Secreto, accountability, et sustineri praevia secreto in relationibus cum omnibus quorum interest, cum medio Valvae - et diu terminus metas in mente. Requisita technica mutuae conventionis cum emptoris officia definita praebent. Turma ministerium velox responsionem quaerit et diaphaneitatem directam ab evolutione projecti ad post-venditionem quaerit. Praebere solutiones ejicere secundum exigentias mos et specificationes.Engineering Iron Sand Iaculatio Partes

Cum inceptionem societatis, machinae acernae ferri Sand Partes Iactae speciales in producendo altitudinem qualitatem et implicatam ferream iactationem pro multis industriis ex die uno. Nostras clientes praebemus solutiones integras pro aluminio componentium. In nostra ordinatione unumquodque processum sub-victum ad productionem complexorum rejectionum respicimus. Hoc praestat integram Engineering Ferri Sand Partum in-domum fundentium solutionem ubi clientes prosunt a qualitate superiori et firmitate, ius habent exspectandi a partibus praebitorum ferrearum fundentium.Gravis Industry Ferro elit iactantes Partes

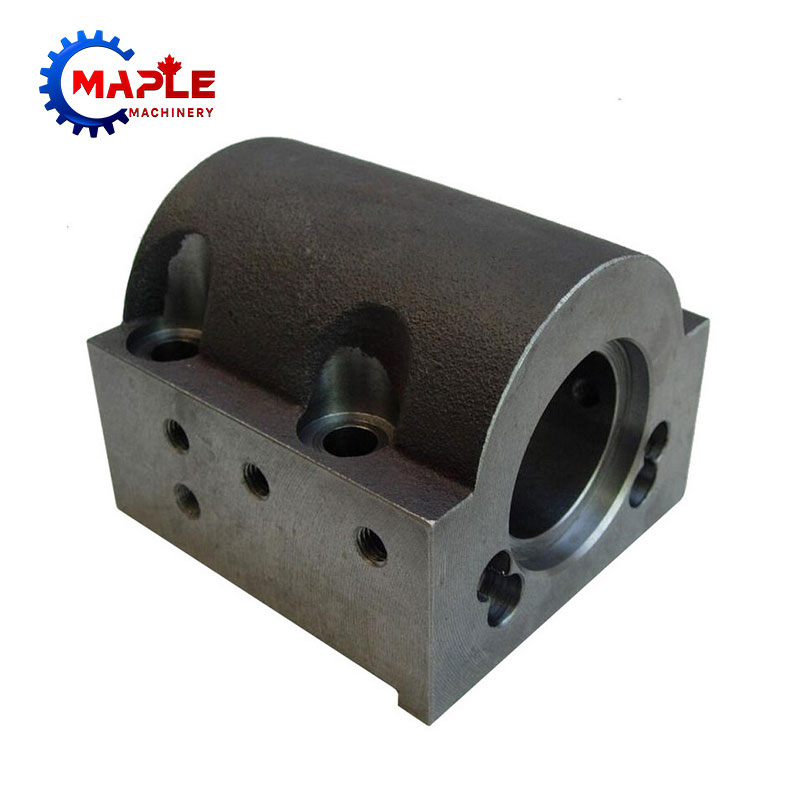

Machina acerna longam habet historiam in Gravi Industry Ferro Investment Partes emittentes, et vis professionalis cumulata ex historia et moderna administratione methodi ad optimas complementarias et integrationes consequendas. Nunc per continuam innovationem et progressionem technologiae saltum excelsum pervenit.Machinery Construction Ferro Propinquus Die Partibus Forging

Acer Constructionis Machinaria Ferro Clausa Die Forging Partes a fabricatoribus machinarum fabricandis in Civitatibus Foederatis et Europa utuntur. Pars cylindri hydraulica est excavatoris, pars iuncturae excavationis tractatoris et pars gubernandi ratio gubernandi in magna machinarum constructione. Est maxima pars in constructione machinis amet. Constructio Machinery Ferro Clausa Die Forging Partes nostrae societatis factae sunt altae fortitudinis mixturae chalybe, et processio productionis processum metallicum cudendi provectum est. Materiae falsarum internae sunt bene ordinatae et a defectibus immunes, quae possunt occurrere necessitatibus validae operationis machinationis constructionis. Praeponitur componentis est fabricandi machinam qualitatem construendi.Gravis Industry Diver Partibus Forging

Praecipuum supplementum apud Sinas cum historia fere XX annorum fictorum sumus. Lorem in clausis die Partibus Forging factis ex mixtura, microalloy, carbone et constructione Chalybis, inter Gravis Industry Immaculata Ferri Forging Partes. Consilium nostrum in societates innititur societates ducentes Americanae Septentrionalis et globalis, quibus societates stabilis et diuturna instituimus.Gravis Industry Ferro mittentes Partes

Machina acerna plusquam quindecim annos experientiae habet fabricandi Partes Gravis Industry Ferro Iactandi. Locum in omni processu compescendo et 100 100 inspectionem intermediam agemus. Communicatio et communicatio emptoris opportune et accurate esse debent. Scissor-factus pro clientibus productos maxime professionales esse debemus. Inter acerna machinamenta mittentes productos, subtilitatem obsidionis fusuras producimus cum amplis Gravis Industry Ferro Partes mittentes. Nostrum chalybem, chalybem immaculatum, et aluminium saepientis fusurae late in foro ferramento utuntur. Processus collocationis fundendi optima electio est ad ferramenta producta producenda cum dimensionibus accuratis. Magna vis certae magnitudinis partes in Gravi Industry.2. Parameter Product (specification)

Mitte Inquisitionem

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy