Nos voca

+86-19858305627

Inscriptio Us

sales@maple-machinery.com

Subtilitas fundendi ad industriam oleum et gas Manufacturers

Officina nostra praebet arenam iacturam, clausa mori cudendo, aperta mori cudendo, etc. Extremum consilium, materias rudis qualitas, princeps effectus ac pretium competitive sunt quae omnis mos velit, et id etiam quod tibi offerre possumus. Summus quale, rationabile pretium, et perfectum servitium.

Hot Products

Cibus Processus Machine Ductile Iron Partibus Iactis

Ab initio eius traditi sumus ad capacitatem fructibus, ut ad mercaturam crescentem postulandam, constanter emendamus Processum Machinae Ductile Ferri Proiciendi Partes et Qualitates. Productio omnium productorum ex machinarum partibus ad partes medias ad suas facultates emendandas. Morbi eget metus.Agricultural Machinery Steel Subcisione Iactis Partibus

Subtilitas iectionis refertur ad terminum generalem pro processu obtinendi quantitatem abiectionis praecise. Comparatus cum processu emissionis harenae traditionalis, subtilitas deiectio accuratiorem quantitatem et superficiem meliorem metam consequi potest. Machinaria acerna in partibus machinalis agriculturae peritia copiosam habet. Machinaria agriculturae Ferro Subsecutio Partes Iactis, in specie. machinis acernis specialitas in ferro certas partes fundendi et agnitionem et fiduciam clientium nostrorum assecutus est.Iron Sand Iactatio Valve Corpus Ductile

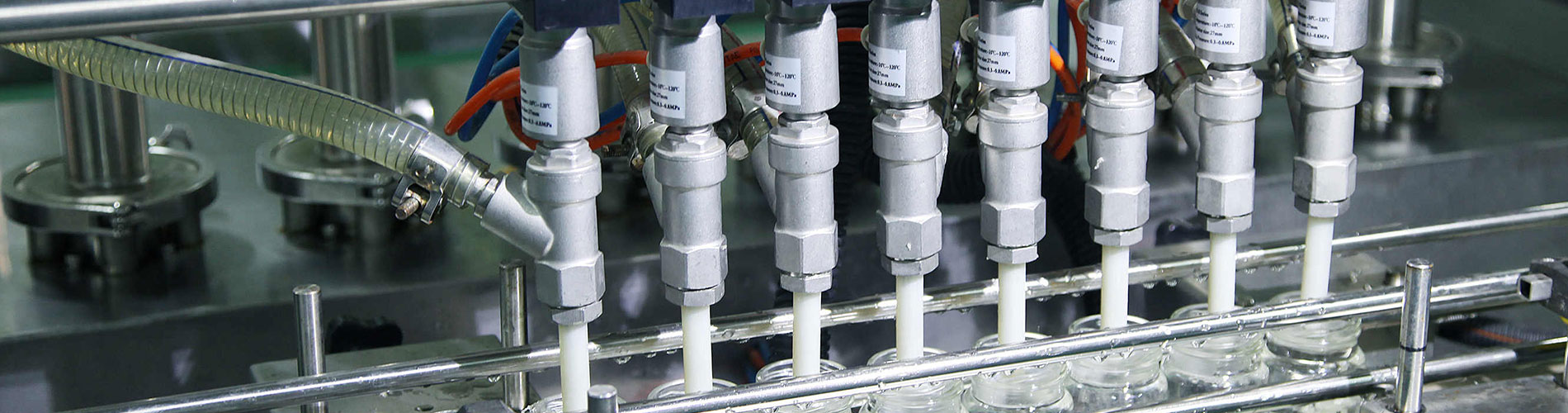

Machina acerna est primarius provisor of ductilis Iron Sand Iactandi valvae corporis solutiones nativus. Nostris quadrigis peritissimus praebet amplam technicam scientiam et experientiam ad solvendas nativus solutiones quae discriminatim ad singulares necessitates nostrorum clientium occurrentes. Summus nos tenemus signa secreto, accountability et sustineri in relationibus nostris cum omnibus quorum interest, cum Valvae medium - et diuturnum metas in mente.Oleum & Gas Industry Steel Investment Iactis Partibus

Maple’ iactus in industria olei et gasi plus quam XV annos fuit, et post diuturnum cooperationem cum fabricatoribus instrumentorum et catenarum copia, amplis peritia habemus. Elit nos praebemus quale oleum & Gas Industry Chalybe Investment Partes mittentes, magna attentione ad corrosionem partium resistentiam et durabilitatem attendunt, et etiam per tempus partus requisiti firmiter permanemus. Ut agricultura, haec industria etiam periodicitatem suam potentialem habet, sic omnes partes tempori tradendae suntHydraulica Systema Ferro Partes Forging

Machina acerna est perfecta et plene integrata cudendo et processui instrumento, specialiter in inceptis fabricandis nativus. Carbon, mixtura et incorrupta ferri HYDRAULICUS Systema Ferri Partes Forging, pondus 0.1kg-60kg. Acer reducere moram curationi caloris, cudendi et partus, ac qualitatem emendare potest.Gravis Industry Grey Ferrum Mittentes Partes

Machina acerna est fabrica Gravis Industry Gray Partes Iactationis, specialiter in productione diversorum generum rejectionum. Unumquodque membrum firmum habet propriam scientiam et technologiam productionis. Omnes fundationes suas actiones independentes habent. Societas consuetudinem ferream Sand Iactationem Partes globales clientes facit

Mitte Inquisitionem

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy