Nos voca

+86-19858305627

Inscriptio Us

sales@maple-machinery.com

Subtilitas Castings et Machined Partes Olei et Gas Industry Manufacturers

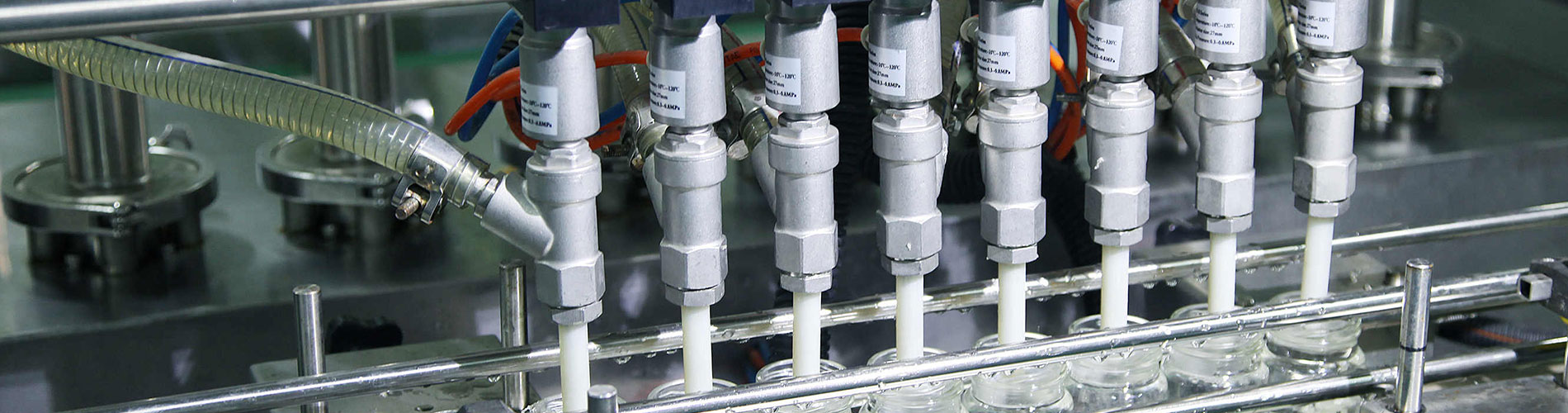

Officina nostra praebet arenam iacturam, clausa mori cudendo, aperta mori cudendo, etc. Extremum consilium, materias rudis qualitas, princeps effectus ac pretium competitive sunt quae omnis mos velit, et id etiam quod tibi offerre possumus. Summus quale, rationabile pretium, et perfectum servitium.

Hot Products

Gravis Industry Diver Partibus Forging

Praecipuum supplementum apud Sinas cum historia fere XX annorum fictorum sumus. Lorem in clausis die Partibus Forging factis ex mixtura, microalloy, carbone et constructione Chalybis, inter Gravis Industry Immaculata Ferri Forging Partes. Consilium nostrum in societates innititur societates ducentes Americanae Septentrionalis et globalis, quibus societates stabilis et diuturna instituimus.Hydraulica Ratio Steel Forging Parts

Machina acerna est superbus fabrica Sinensium fabricans solutiones cudebat per 15 annos. Baculus peritus noster fabricas ferreas immaculatam qualitatem altam producebat, fortem famam tamquam ducem mercatum aedificans operando cum clientibus per orbem terrarum. Intellegimus postulationem clientium nostrorum pro Systemate Hydraulico Steel Partes Forging et pressionem pro celeriter turnaround. Laboramus cum clientibus systematis Hydraulicis ad moderandas sumptus servato altas fabricationes, qualitates et signa logistics quae requirunt. Munus integrum offerimus cum consilio, instrumento et instrumento confectionisMarine Stainless Steel Iactis Partibus

Maple machinery is a professional manufacturer located in Ningbo, China. More than 15 years of experience in the steel industry. Our products mainly include Marine Stainless Steel Casting Parts. Our products have been exported to many countries in Europe and America. We have a wealth of foundry experience, but also a number of stable Marine industry customers.产品内容 Product Introduction Maple machinery offers a wide range of custom Marine Stainless Steel Casting Parts. Stainless steel is resistant to corrosion and heat, has aesthetic appeal and low life cycle cost, is fully recyclable and has a good strength-to-weight ratio. We offer austenite, ferrite, martensite and biphase grades: we have hot or cold rolled and various surface treatments such as bright annealing. You can count on our experience. 2. Product Parameter (Specification) Item Marine Stainless Steel Casting Parts Roughness Ra 1.6 Tolerance ±0.01mm Material Casting Steel Certification ISO 9001:2015 Weight 0.01-2000KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Investment Casting Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Service for Marine Maple machinery has been the most demanding supplier of Marine Stainless Steel Casting Parts for more than 15 years. Our reputation has earned us partners and valued customers who follow the most stringent requirements in terms of microstructure integrity, dimensional tolerances and quality control. Our products meet customers' requirements and standards. 4.Supporting Service for Marine As mentioned above, in order to work in adverse conditions, the performance of the Marine Stainless Steel Casting Parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Mining Industry We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Marine Stainless Steel Casting Parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for The Marine We have manufactured a wide range of Marine Stainless Steel Casting Parts. The following are typical products: Ground engaging tools: drill bits, carbide tipped tool, forged bucket tooth, auger.... 6.Why Investment Casting Investment casting is a leading process used for the production of high-quality castings and is used to make metal alloys. The key advantage of the investment casting process is that it can help to cast metals with high melting temperatures and create parts with complex geometry that are much needed in industries like aircraft, automotive, and military. As professional investment casting manufacturer, our specialized technique is widely applied to get heavier, stronger, and complex shapes for investment castings. When you trade with us, you get several benefits such as lower costs, a cheaper molding process for complex designs, and higher accuracy. Another competitive benefit enjoyed by Maple Machinery is its leading position in China for casting technology. We will provide precision castings and micron-level processing services.Mining Industry Ductile Iron Partibus Iactis

Ab initio, Acer famam singularis servitutis emptoris meruit. Sumus fons comprehensivus pro omnibus Mining Industry Ductilis Ferrum Iactis Partibus. Servitium proprietas nostra est, et laboramus ad liberandos fructus quos indigetis, cum eis opus est. Commissi sumus ut alta qualitas products comparandis pretiis provideat ut satisfactio emptoris.Oleum & Gas Industry Steel Forging Parts

Ad decennium, acerna machinatio majoris instrumenti ad Olei et Gas industriae fuit, quae qualitatem et pretia competitive praebens. Ob duras condiciones environmental in Oleo et Gas industria, underaqua, superficie et industria fractura hydraulica, Acer summas qualitates materiae et accurationem fabricandi per facultates, facultatem et experientiam cudendi, et optimam Olei & Gas Industry Steel Partes Forging efficit. brevissimum tempus partus.Gravis Industry Ferro mittentes Partes

Machina acerna plusquam quindecim annos experientiae habet fabricandi Partes Gravis Industry Ferro Iactandi. Locum in omni processu compescendo et 100 100 inspectionem intermediam agemus. Communicatio et communicatio emptoris opportune et accurate esse debent. Scissor-factus pro clientibus productos maxime professionales esse debemus. Inter acerna machinamenta mittentes productos, subtilitatem obsidionis fusuras producimus cum amplis Gravis Industry Ferro Partes mittentes. Nostrum chalybem, chalybem immaculatum, et aluminium saepientis fusurae late in foro ferramento utuntur. Processus collocationis fundendi optima electio est ad ferramenta producta producenda cum dimensionibus accuratis. Magna vis certae magnitudinis partes in Gravi Industry.2. Parameter Product (specification)

Mitte Inquisitionem

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy