Nos voca

+86-19858305627

Inscriptio Us

sales@maple-machinery.com

Ferrum pro oleo et gas Operations Manufacturers

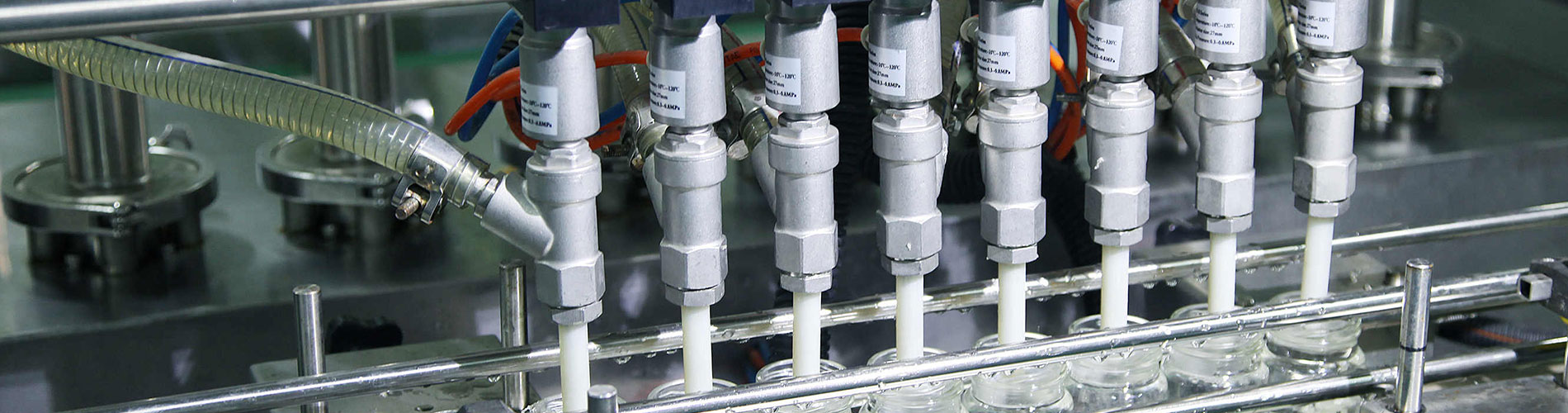

Officina nostra praebet arenam iacturam, clausa mori cudendo, aperta mori cudendo, etc. Extremum consilium, materias rudis qualitas, princeps effectus ac pretium competitive sunt quae omnis mos velit, et id etiam quod tibi offerre possumus. Summus quale, rationabile pretium, et perfectum servitium.

Hot Products

Off via Industry Ferro elit iactantes Partes

Acer Machinaria utitur technologia professionali et peritia ad designandum et producendum summus qualitas products. Coniecturae subtilitate a nobis factae utimur in toto orbe terrarum cursu plenas blasphemantes. Collaboramus et laboramus cum pluribus magnarum machinarum ferriviarum partibus in mundo. Our customers use our Off Highway Industry Steel Investment Parts Iactantes cum fiducia propter nostram comprehensivam qualitatem moderandi signa. Spondemus hasteel fusuras et malleolos a nobis factas pro Industriis Highway certas esse.Cibus Processus Machina Steel Lost Cera Iactis Partibus

Machinaria acerna est metallorum internationalis fabrica, quae admixtiones et processus elaborandi ad altas operationes partium iactarum pro machinis, oleis et gas, in molendinis et hydraulicis, ferro et per multos annos, fuit. Acer machinalis industriae famam globalem acquisivit ad emptores requisita per eius peritia technica solida nota. Acer machinae machinamentum est ut clientes suos cum qualitate Cibus Processus Machina Ferro Amissa Cera Partes fundens per culturam perficiendam nititur in innovatione, fide et tutela environmental.Oleum & Gas Industry Steel Subcisione Iactis Partibus

Machinatio acerna commissa est ad mercatum littoris suppeditandi cum Ferro Praecisione Partes mittentes ad Industry Olei & Gas. Ferro Subsecutio Partes mittentes essentiales habentur pro extractione olei et gasi - anuli e ferro admixto, armamento, mechanica tubinga - adhibiti ad productionem humidam efficiendam. Ut postulationi mercatus domesticae et internationalis occurrat, societas in accessione facultatis productionis investit.Construction Machinery Steel Forging Parts

Machina acerna rectam solutionem habet. Utere CNC machinis machinis uti ad processum vestibulum simpliciorem reddendo. Iuvat te accelerare productionem partium quae molis discursum cum summis praecisione et cura. Machinatio acerna te celeriter praebere potest online CNC machinatio Constructionis Machineria Immaculata Steel Partes Forging secundum specifica requisita tua. Tibi praebemus machinam celeris serviendi quote ac processus partes tibi citissimo tempore.Valvae Steel Partes Forging

We at Maple machinery guarantee the quality and impeccable service of every Valve Steel Forging parts. We strive for excellence every day, using all of our expertise and tremendous commitment to ensure maximum efficiency. We aim at innovation to create a better future and bravely face every new challenge. Product Introduction The different Forging techniques offered by Maple machiney Forging solutions enable us to forge the different Valve Steel Forging parts of valves all of which are designed to the customer's requirements and are also checked and verified in a simulator before forging. The resources and skills of our staff enable us to forge any type of material that is processed on our heat treatment equipment and completed after conducting final destructive and non-destructive tests. They are provided on delivery terms agreed with the customer and include all required documents and certificates. 2. Product Parameter (Specification) Item Valve Steel Forging parts Roughness Ra 1.6 Tolerance ±0.01mm Material Alloy Steel Certification ISO 9001:2015 Weight 0.01-60KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Closed Die Forging Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Services for Valve Our Valve Steel Forging parts have a worldwide reputation for their high quality and reliability. With our state-of-the-art testing laboratories and highly qualified workforce, we combine the highest standards of technology, quality and productivity. Accurate delivery time, fast service, we get the customer's praise. 4.Supporting Service for Valve parts As mentioned above, in order to work in adverse conditions, the performance of the Valve Valve Steel Forging parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Agricultural Machinery We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Valve Steel Forging parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for the Valve We have manufactured a wide range of Valve Steel Forging parts. The following are typical products: Valve joint, Ball valve body, Gate valve body, Choke valve body,Beer valve body,Purification water brass,Hybrid valve, .... 6. Why Closed Die Forging Compared with casting, forging has its special advantages: 1. In the case of the same material, the mechanical properties of forgings are better than those of castings. 2. The forgings strength is higher and the fatigue resistance is stronger. 3. The forgings has better compactness. 4. There are no internal defects and surface defects. 5. Fast production speed, high efficiency, suitable for mass production of products. 6. The product quality is stable.Machinery Construction Steel Investment Iactis Partibus

Machina acerna est officina moderna quae specialitas in fundendis et machinis, et creditum nomen est Machinery Machinery Chalybis Constructione Partibus Iactis. Praestantissimis ingeniis iugales sumus et firmiter credimus congruere cum technologiae opportunis necessitatibus emptori. Omnes nostri liminis et machinae tabernam ISO9001:2015 certificationem transierunt. Quid locorum opportunitates nobis praebet opportunis locus Ningbo est, ut urbs portus, quae negotium exportandi auget.

Mitte Inquisitionem

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy