Nos voca

+86-19858305627

Inscriptio Us

sales@maple-machinery.com

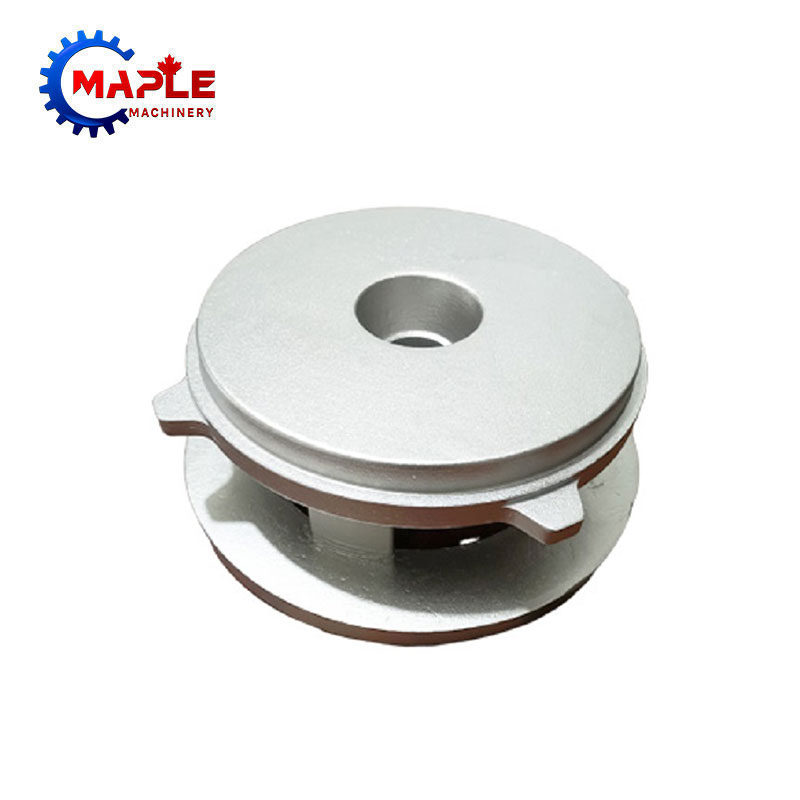

Utilitas vehiculum ferreum investment mittentes partes Manufacturers

Officina nostra praebet arenam iacturam, clausa mori cudendo, aperta mori cudendo, etc. Extremum consilium, materias rudis qualitas, princeps effectus ac pretium competitive sunt quae omnis mos velit, et id etiam quod tibi offerre possumus. Summus quale, rationabile pretium, et perfectum servitium.

Hot Products

Iron Sand Iactatio Valve Corpus Ductile

Machina acerna est primarius provisor of ductilis Iron Sand Iactandi valvae corporis solutiones nativus. Nostris quadrigis peritissimus praebet amplam technicam scientiam et experientiam ad solvendas nativus solutiones quae discriminatim ad singulares necessitates nostrorum clientium occurrentes. Summus nos tenemus signa secreto, accountability et sustineri in relationibus nostris cum omnibus quorum interest, cum Valvae medium - et diuturnum metas in mente.Engineering Steel Iactis Partibus

Machinaria acerna plus quam XV annos experientiae in Ferro industriae habet, ita etiam multum experientiam habemus in fabricandis Engineering Civili Partes Ferro emittentes et nostras proprias perceptiones singulares habemus. Scimus quid vobis praecipuum sit: praeter qualitatem, traditio- nem et pretium, solutio praecedit. Scientia structuralis, delectu applicatio, cognitio technologiae materialis et electio technologiae effectio supponitur.Gravis Industry Iron Sand Iactis Partibus

Machinaria acerna, in Ningbo, Sinis sita, est inventarium quae amplis Industry Ferrum Sand mittentis partes graves ad applicationes graves producit. Praecipuas etiam res machinas perficiendi efficimus, inclusas anulos Diesel engine anulos, cylindros lineros et baculos connexos. Superbi sumus dicere meruisse famam in supplementum alicuius summae qualitatis Iron Arena in orbem mittentes. Quia nostra qualitas et officium mos pro clientibus implentur.Hydraulic System Steel Investment Iactis Partibus

Acer clavis ludio ludius est in processu industriae in agro ad certas obsidiones mittentes. Acer multa evolvit Hydraulica Systema Steel Investment Partes mittentes, quae plerumque in mixturas speciales coniciuntur. Praecipuae hae admixtiones adhibentur, quia elementa plerumque in ambitibus mordax (duris) laborant, magnas differentias temperaturas habent, vel durissimas, validas, vel leves fructus requirunt.Mining Industry Iron Sand Iactis Partibus

Acer Machinaria praebet ieiunium et qualitatem ferrum et ferrum et partes ferreas et Mining Industry Iron Sand Partes Iactandi. Manipulus professionalium fundationum, plasmatorum et metallurgicorum multos annos experientiae habet in continua cooperatione cum clientibus, et potest technicas materias et peritia applicare ad certos eventus omni tempore curare.Valvae Steel Iactis Partibus

Qualitas moderatio machinis acernis est strictissima. Valvae Steel Partes fundentes productum est quod magna quantitate quotannis producimus, sed acerna machinatio numquam remittit. Qualitas et salus maculosa ratio in omnibus officinis adhibetur. Periodice firmitatem omnium testium et instrumentorum mensurandi et artes opificum reprehendo. Necessarium est consilium productionis refrenare et non destructivum efficere ut probatio principalis media qualitatis qualitatis.

Mitte Inquisitionem

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy