Nos voca

+86-19858305627

Inscriptio Us

sales@maple-machinery.com

Valvae components per immaculatam ferro ejectionem Manufacturers

Officina nostra praebet arenam iacturam, clausa mori cudendo, aperta mori cudendo, etc. Extremum consilium, materias rudis qualitas, princeps effectus ac pretium competitive sunt quae omnis mos velit, et id etiam quod tibi offerre possumus. Summus quale, rationabile pretium, et perfectum servitium.

Hot Products

Off via Industry Diver mittentes Partes

Ut optimos parametros Jactantes productum petitum praebeat, machinae acernae fabricare Off Highway Industry Stainless Steel Partes Jacentes utentes novissimam CAD technologiam ut clientes nostros cum cerae injectione formas ad sumptus competitive praebeant. Fixtura quae praebet et sustentat consistentiam dimensivam formae iniectionis cerae per se designatum est secundum dimensiones tractus technicarum partium ad accurate mensuras iterare.Valvae Steel Investment Iactis Partibus

In machinis acernis, experientiam habemus amplam mittendi pro Valve Steel Investment Partes mittentes, ut clientes nostros ad altam qualitatem dejectiones ab obsidione mittentis processum oeconomicum sumptus consequantur. Optimum technicum equos habemus cum multis annis experientiae ut tibi optimam obsidendi rationem de consilio praebeas. Quodlibet auxilium opus est - ex recognitione simplici tolerantiae ad plenam machinationem concurrentem - praesto est apud nostrum locum fornacem. Valvae Steel Investment Partes Iactis, acerna machinatio tibi optimo praebere potest.Machinery Construction Ferro Propinquus Die Partibus Forging

Acer Constructionis Machinaria Ferro Clausa Die Forging Partes a fabricatoribus machinarum fabricandis in Civitatibus Foederatis et Europa utuntur. Pars cylindri hydraulica est excavatoris, pars iuncturae excavationis tractatoris et pars gubernandi ratio gubernandi in magna machinarum constructione. Est maxima pars in constructione machinis amet. Constructio Machinery Ferro Clausa Die Forging Partes nostrae societatis factae sunt altae fortitudinis mixturae chalybe, et processio productionis processum metallicum cudendi provectum est. Materiae falsarum internae sunt bene ordinatae et a defectibus immunes, quae possunt occurrere necessitatibus validae operationis machinationis constructionis. Praeponitur componentis est fabricandi machinam qualitatem construendi.Valvae Steel Partes Forging

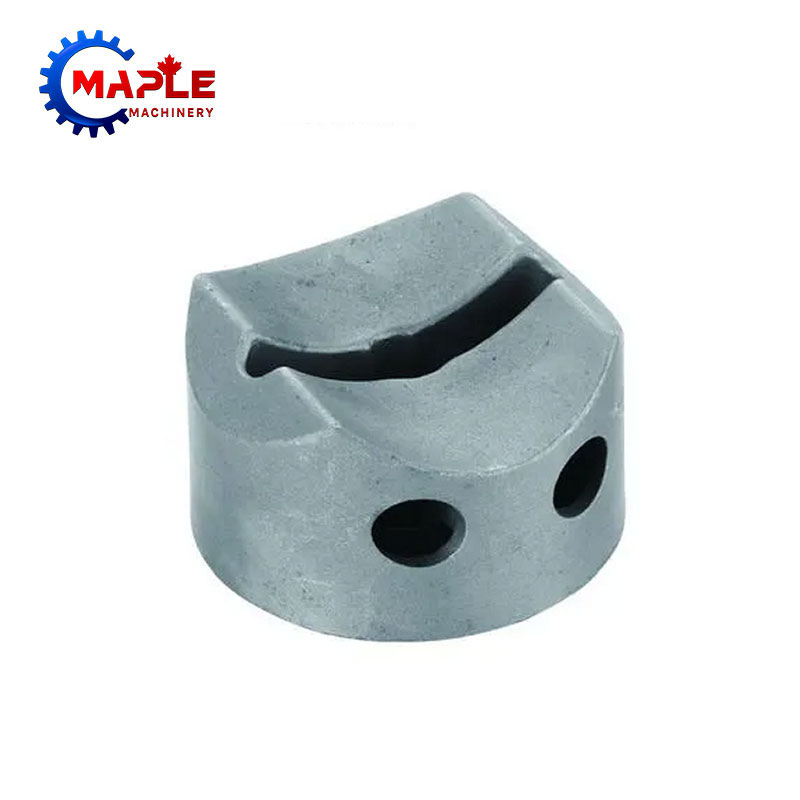

We at Maple machinery guarantee the quality and impeccable service of every Valve Steel Forging parts. We strive for excellence every day, using all of our expertise and tremendous commitment to ensure maximum efficiency. We aim at innovation to create a better future and bravely face every new challenge. Product Introduction The different Forging techniques offered by Maple machiney Forging solutions enable us to forge the different Valve Steel Forging parts of valves all of which are designed to the customer's requirements and are also checked and verified in a simulator before forging. The resources and skills of our staff enable us to forge any type of material that is processed on our heat treatment equipment and completed after conducting final destructive and non-destructive tests. They are provided on delivery terms agreed with the customer and include all required documents and certificates. 2. Product Parameter (Specification) Item Valve Steel Forging parts Roughness Ra 1.6 Tolerance ±0.01mm Material Alloy Steel Certification ISO 9001:2015 Weight 0.01-60KG Machining CNC Heat Treatment Quenching & Tempering Inspection MT/UT/X-Ray Lead Time 30 Days Package Plywood Case Method Closed Die Forging Capacity 50000 Pcs / Month Origin Ningbo, China 3. Maple’s Services for Valve Our Valve Steel Forging parts have a worldwide reputation for their high quality and reliability. With our state-of-the-art testing laboratories and highly qualified workforce, we combine the highest standards of technology, quality and productivity. Accurate delivery time, fast service, we get the customer's praise. 4.Supporting Service for Valve parts As mentioned above, in order to work in adverse conditions, the performance of the Valve Valve Steel Forging parts must be excellent. Therefore, it’s not enough to only produce raw castings or forgings, but also need heat treatment, machining, surface treatment, NDT testing, etc. Heat treatment: heat treatment is the critical step to improve the mechanical properties of the workpiece. We can formulate the process according to the strength requirements of the parts, and improve the mechanical properties of the parts such as hardness, yield strength, tensile strength and elongation by heat treatment Machining: we have our own machine shop, and can complete almost all machining requirements with advanced equipment. Surface treatment: the purpose of surface treatment is to make parts work in adverse environment. Zinc plating can prevent parts from rusting; Nickel plating can enhance the wear resistance and corrosion resistance of parts; Phosphating can prevent parts from corrosion… Non-destructive testing (NDT): NDT is the last and most important step. Maple will NDT the parts to ensure that there are no surface defects (such as cracks, sand holes, blow holes) and no internal defects (shrinkage and slag) on the delivered parts. Common Material for Agricultural Machinery We have the ability to manufacture all steel standard materials as well as special materials. The following are our common materials for manufacturing Valve Steel Forging parts: Carbon Steel:1015, 1020, 1035, 1045, 20Mn, 25Mn, A570.GrA, SJ355, C45… Alloy Steel:4130, 4135, 4140, 4340, 8620, 8640, 20CrMo, 42CrMo4, 34CrNiMo6, 25CrMo… Stainless steel:304, 304L, 316, 316L, 410, 416, CF8, CF8M, PH17-4, CK20… Gray Iron:GG-15, GG-20, GG-25, Class 20B, Class 25B, Class 30B, GJL-250, GJL-300… Ductile Iron:GGG-40, GGG-50, 60-40-18, 65-45-12, 70-50-05, 80-55-06 QT500-7, QT400-18, QT700-2 … High Chromium cast iron:15%Cr-Mo-HC, 20%Cr-Mo-LC, 25%Cr… Aluminum:AlSi7Mg, AlSi12, AlSi10Mg, A356, A360… High Manganese steel: X120Mn12, Mn12, Mn13… 5.The Parts We Supplying for the Valve We have manufactured a wide range of Valve Steel Forging parts. The following are typical products: Valve joint, Ball valve body, Gate valve body, Choke valve body,Beer valve body,Purification water brass,Hybrid valve, .... 6. Why Closed Die Forging Compared with casting, forging has its special advantages: 1. In the case of the same material, the mechanical properties of forgings are better than those of castings. 2. The forgings strength is higher and the fatigue resistance is stronger. 3. The forgings has better compactness. 4. There are no internal defects and surface defects. 5. Fast production speed, high efficiency, suitable for mass production of products. 6. The product quality is stable.Redivivus Industry Ferro elit iactantes Partes

Machina acerna sita est in Ningbo, urbe prope portum, quae ad opus vecturae valde utile est. Conducit ad commutationem productum. Explicatio Redivivus Industry Ferro Investment Partes Jacentes Ostendit sursum flecte in mundo. acernis machinamentis in perennem inquisitionem redivivus Industry Steel Investment Conjecting Partes versatus est.Gravis Industry Ferro Partibus Forging

Machina acerna est celeriter crescens provisor fabricandi producti in Sinis, in provocationibus occurrens productorum hodierni cudendi. Princeps effector ab initio fuit et unus e praecipuis fabricatoribus praebitorum varii gradus ferri ad Gravis Industry. Machina acerna cognoscitur a clientibus honestis et agenciis probatis pro qualitate Gravis Industry Ferro Forging Partes. Societas nostra semper in technologia antecedens tendit ut meliores fructus cudendo anno post annum praebeat.

Mitte Inquisitionem

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy