Nos voca

+86-19858305627

Inscriptio Us

sales@maple-machinery.com

Valvae Steel Iactis Partibus Manufacturers

Officina nostra praebet arenam iacturam, clausa mori cudendo, aperta mori cudendo, etc. Extremum consilium, materias rudis qualitas, princeps effectus ac pretium competitive sunt quae omnis mos velit, et id etiam quod tibi offerre possumus. Summus quale, rationabile pretium, et perfectum servitium.

Hot Products

Industry Iron Sand Iactis Partibus

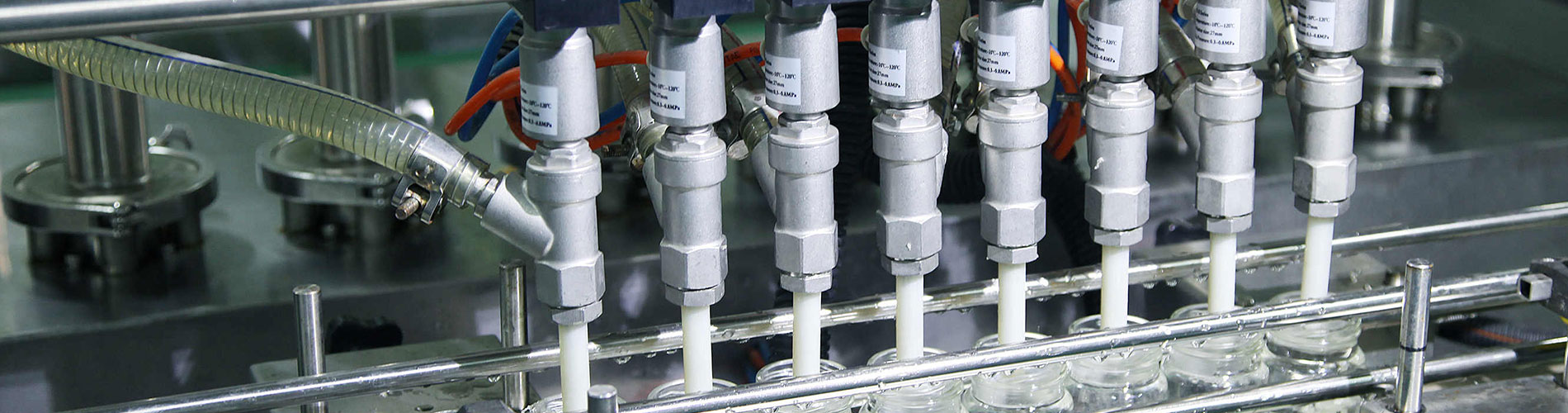

Machina acerna est fabrica industriae ferreae Sand Partes fundentis, specialiter in productione diversarum specierum iactationum. Unumquodque membrum firmum habet propriam scientiam et technologiam productionis. Omnes fundationes suas actiones independentes habent. Societas consuetudinem ferream Sand Iactationem Partes globales clientes facitValvae Diver partes Forging

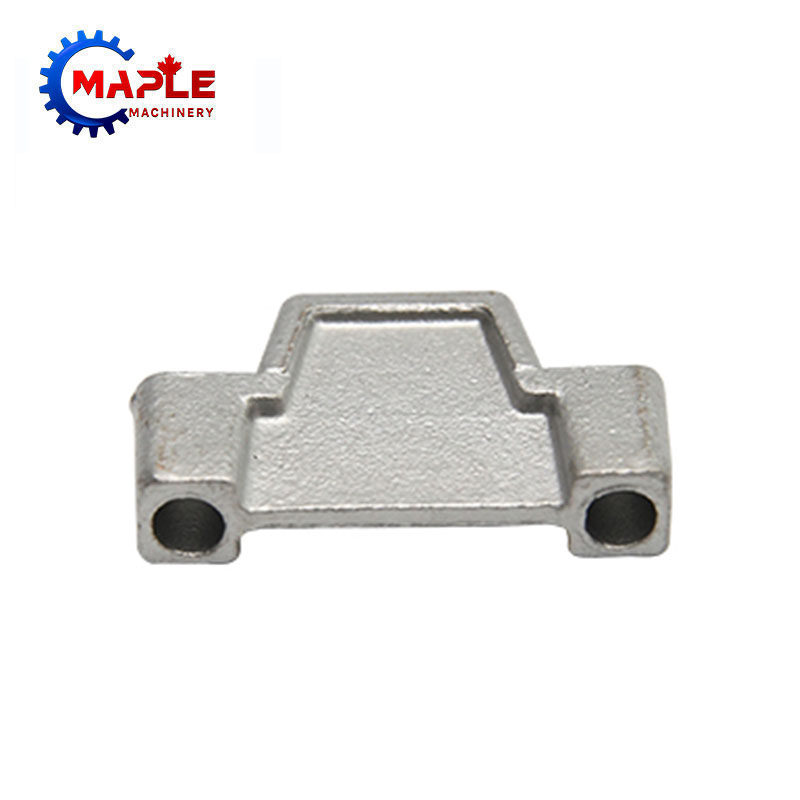

Processus Valvae Stainless Steel Forging Parts Nos omnes artes conventionales pro partibus cudendo habemus. Scopus officiorum nostrorum includit processus ferramentorum immaculati in ferramentis moriendi, praesertim molendi et convertendi operationes in instrumentorum machinarum CNC machinarum. Secundum exigentias clientium, cooperationem cum aliis officinis praebere possumus.Redivivus Industry Ferro elit iactantes Partes

Machina acerna sita est in Ningbo, urbe prope portum, quae ad opus vecturae valde utile est. Conducit ad commutationem productum. Explicatio Redivivus Industry Ferro Investment Partes Jacentes Ostendit sursum flecte in mundo. acernis machinamentis in perennem inquisitionem redivivus Industry Steel Investment Conjecting Partes versatus est.Hydraulic System Iron Sand Iactus Partes

Acer Leaf Machinery Co., Ltd. producit Systema Hydraulica Iron Sand Partes fundentes, et ingenium nostrum 15 annis praeteritis perfecti fuimus. Scientiam nostram utimur ad transeundum in optima Systemate Hydraulico Ferrum Sand mittentes exercitia et artes, et novissimos progressus in processibus mittendis adhibemus. Societas maxime spectat ad formam arenam proiectionem, putamen dejectionem et ceram dejectionem amissam, et constanter dilatat facultates sustinendas, technologiam, apparatum et officia.Valvae ferreae arenae emissae partes

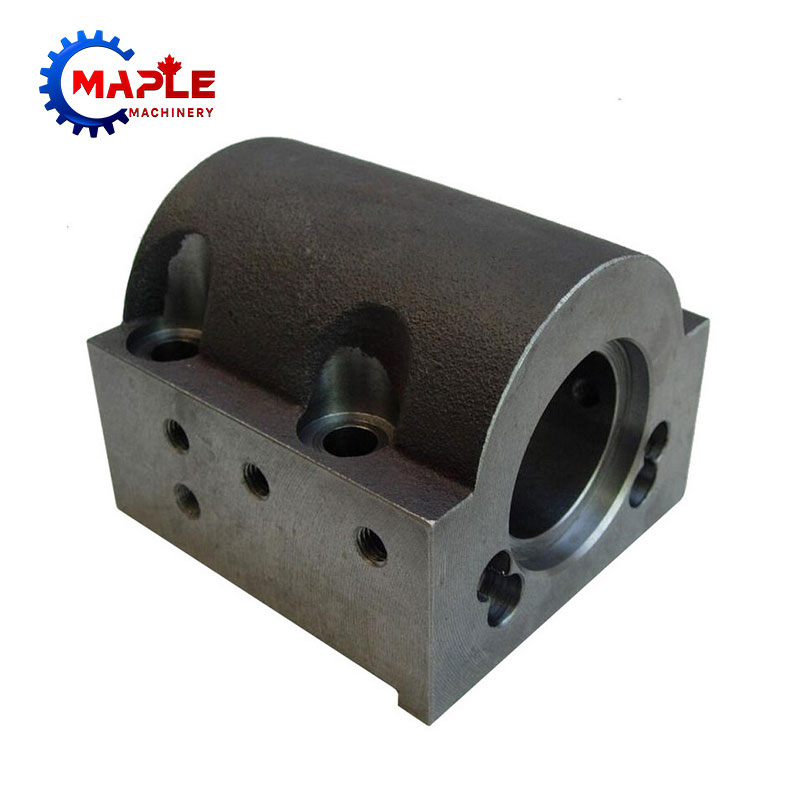

Acer, in Sinis sita, stat in fronte excellentiae fabricandae, specialiter in Partibus Valvae Iron Sand Cast. Cum umbilico in tribus his cardinis cardinis, nostrum studium ad praecisionem et qualitatem indeclinabilis est. Artificia technicae artis provectae coniungimus et in technologia ferrea harenae nostrae processibus eiectis coniungimus, ut quaelibet pars valvae maximis signis occurrat. Sicut nomen creditum industriae, peritia Maple iacet in solutionibus ad formandam solutionem pro diversa applicationum amplitudine tradendo, solidans statum nostrum ut certa provisor valvae ferreae arenae iactae partes in foro Sinensi et ultra.Off via Industry Ferro Propinquus Die Partibus Forging

MapleMachinery specialitas in ferramentis clausis alea producendis. Nostra producta includunt malleolum metallicum sicut aluminium, chalybem carbonum, offensionem chalybem et chalybem immaculatam, quae in via off, agriculturae, automotivae, constructionis et fodiendi industrias adhibentur. Providemus summus qualitas Off Highway Industry Steel Clausa Die Forging Partes et optimum pretium totalis quam mos exspectationes excedunt.

Mitte Inquisitionem

X

We use cookies to offer you a better browsing experience, analyze site traffic and personalize content. By using this site, you agree to our use of cookies.

Privacy Policy